FM-E Tsis Siv Neeg Vertical Laminating Tshuab

| Qauv | FM-E1080 |

| FM-1080-Max. ntawv loj-mm | 1080 × 1100 hli |

| FM-1080-Min. ntawv loj-mm | 360 × 290 hli |

| Ceev - m / min | 10-100 |

| Daim ntawv thickness-g / m2 | 80-500 |

| Overlap precision-mm | ≤ ± 2 |

| Zaj duab xis thickness (common micrometer) | 10/12/15 |

| Cov kua nplaum tuab-g / m2 | 4-10 |

| Pre-gluing zaj duab xis thickness-g / m2 | 1005,1006,1206 (1508 thiab 1208 rau sib sib zog nqus embossing ntawv) |

| Non-stop Feeding qhov siab-mm | 1150 |

| Sau ntawv qhov siab (incl. pallet)-mm | 1050 |

| Main lub cev muaj zog-kw | 5 |

| Hwj chim | 380V-50Hz-3PMachine sawv zog: 65kw Ua haujlwm fais fab: 35-45kw Cua sov zog 20kwBreak xav tau: 160A |

| 3 theem ntxiv rau lub ntiaj teb thiab nruab nrab nrog lub voj voog | |

| Lub tshuab nqus tsev twj | 80psi:3 qw |

| Roll ua hauj lwm siab-Mpa | 15 |

| Cua compressor | Volume ntws: 1.0m3 / min, Rated siab: 0.8mpa Lub zog: 5.5kw Cua ntim yuav tsum tsis tu ncua. Cov cua nkag: 8mm txoj kab uas hla cov yeeb nkab (Qhia kom haum qhov chaw nruab nrab cua) |

| Cable thickness - hli 2 | 25 |

| Qhov hnyav | 8 000kgs |

| Dimension (zeeg) | 8000 * 2200 * 2800mm |

| Chaw thau khoom | Ib qho ntawm 40 "HQ |

Lus Cim: txais customize loj loj ntawm lub tshuab nyob ntawm tus neeg siv khoom xav tau. 1050 * 1250; 1250 * 1250mm; 1250 * 1450mm, 1250 * 1650mm

FM-E tag nrho Tsis Siv Neeg Vertical High-precision thiab ntau lub luag haujlwm laminator ua cov khoom siv tshaj lij siv rau cov yas zaj duab xis laminating rau saum npoo ntawm lub tshuab luam ntawv teeb meem.

F Water-based gluing (waterborne polyurethane nplaum) qhuav laminating. (dej-raws li kua nplaum, roj-raws li kua nplaum, tsis-kua nplaum zaj duab xis)

F Thermal lamination (Pre-coated / thermal zaj duab xis)

F Film: OPP, PET, PVC, METALIC, thiab lwm yam.

Muaj feem xyuam rau laminating nyob rau hauv ntim, ntawv thawv, phau ntawv, ntawv xov xwm, daim ntawv qhia hnub, thawv, handbags, Khoom plig lub thawv, Wine ntim ntawv txhim kho cov ntawv luam ntawv qib, thiab ua tiav lub hom phiaj ntawm plua plav-pov thawj, dej-pov thawj, roj pov thawj. Nws yog qhov kev xaiv zoo tshaj plaws rau kev luam ntawv thiab laminating lag luam ntawm txhua qhov teev.

Daim ntawv thauj khoom loj ntawm kev tshuaj ntsuam sau sau, tag nrho tsis siv neeg lub tshuab tag nrho.

Cov cuab yeej zoo li kev tsim qauv tsim, tshuaj tsuag-xim txheej txheem, siv tau thiab zoo nkauj.

High quality pneumatic conveying paper feeder nrog 4 suckers rau nqa daim ntawv thiab 4 suckers rau conveying ntawv kom ruaj khov thiab ceev daim ntawv pub. Tsis nres thiab nrog pre-pile unit.overlap yog tswj los ntawm servo lub cev muaj zog, xyuas kom raug.

Daim ntawv conveying phaj nrog 304 corrugated stainless hlau phaj.

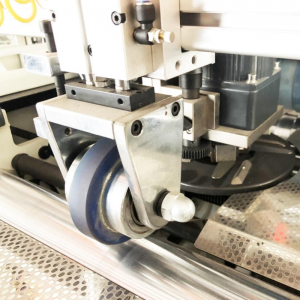

Vertical dual functions laminator chav tsev, 380mm txoj kab uas hla lub ntsiab steel cua sov cov menyuam yog tswj los ntawm electromagnetic cua sov system, high efficiency thiab lub zog txuag, nws yuav xyuas kom meej cov khoom zoo 'film laminating yuav tsum. 800mm txoj kab uas hla kom qhuav cua sov cov menyuam, 380mm txoj kab uas hla roj hmab siab cov menyuam, Thickened chrome plated saum cov menyuam, Qhia cov menyuam thiab cov kua nplaum platewith Teflon ua kua nplaum yooj yim los ntxuav.

Round riam muaj nuj nqi haum rau BOPP thiab OPP zaj duab xis. Kub riam ua haujlwm haum rau PET thiab PVC zaj duab xis slitting.

Kev teeb tsa hluav taws xob feem ntau yog siv rau Taiwan Delta hluav taws xob tswj qhov system thiab Fabkis Schneider hluav taws xob khoom siv.

Tsev khaws khoom: Tsis nres tsis siv neeg xa khoom zoo.

Kev txhawb nqa lub laub nqa hloov yob zaj duab xis, Ib tus neeg ywj pheej ua haujlwm.

| FEEDER PART | FM-E | |

| 1 | Jet-feeding hom | ★ |

| 2 | Kev kub ceev Feeder | ★ |

| 3 | Feeder servo tsav tsheb | yeem |

| 5 | BECKER Lub tshuab nqus tsev twj | ★ |

| 6 | Pre stack ntaus ntawv tsis nres pub ntawv | ★ |

| 7 | Overlap servo tswj | ★ |

| 8 | Sab guage | ★ |

| 9 | Pleev daim ntawv nrog Max & Min txwv | ★ |

| 10 | Dust remover unit | ⚪ |

| 11 | Qhov rai laminating chav tsev (txheej & ziab) | ⚪ |

| LAMINATING UNIT | ||

| 1 | Pab cua sov qhov cub | ★ |

| 2 | Qhuav roller txoj kab uas hla | 800 hli |

| 3 | Qhuav roller Electromagnetic cua sov system | ⚪ |

| 4 | Intelligent kub qhov system | ★ |

| 5 | Pab qhov cub pneumatic qhib | ⚪ |

| 6 | Cua sov yob nrog Chromium kho | ★ |

| 8 | Electromagnetic cua sov system | ★ |

| 9 | Roj hmab siab yob | ★ |

| 10 | Siab tsis siv neeg kho | ★ |

| 11 | Tsav Chain KMC-Taiwan | ★ |

| 12 | Daim ntawv nco nrhiav | ★ |

| 13 | Gluing system Teflon kho | ★ |

| 14 | Tsis siv neeg lubrication & txias | ★ |

| 15 | Removable touch screen tswj board | ★ |

| 16 | Txhawb nqa lub laub nqa | ★ |

| 17 | Multi yob zaj duab xis ua haujlwm-Slip axis | ⚪ |

| 18 | Ob chav kub cov menyuam xovxwm | ⚪ |

| 19 | Gluing rollers Independent tswj | ⚪ |

| AUTOMATIC CUTTING UNIT | ||

| 1 | Round riam unit | ★ |

| 2 | Chain riam unit | ⚪ |

| 3 | Kub riam chav tsev | ⚪ |

| 4 | Sand belt break film device | ★ |

| 5 | Bounce roller anti daim ntawv curling | ★ |

| 6 | Ntsia hlau hom cua compressor | ⚪ |

| COLLECTOR | ||

| 1 | Tsis nres tsis siv neeg xa khoom | ★ |

| 2 | Pneumatic patting thiab sau qauv | ★ |

| 3 | Daim ntawv txee | ★ |

| 4 | Photoelectric induction daim ntawv lub caij nplooj zeeg | ⚪ |

| 5 | Tsis siv neeg deceleration ntawv sau | ★ |

| Electronic PARTS | ||

| 1 | Cov khoom siv hluav taws xob zoo | OMRON / SCHNEIDER |

| 2 | Tswj system | Delta-Taiwan |

| 3 | Servo lub cev muaj zog | Weikeda-German technology |

| 4 | Main Monitor kov npo-14 nti | Samkoon-Japanese technology |

| 5 | Saw riam & riam kub kov npo-7 nti | Samkoon-Japanese technology |

| 6 | Inverter | Delta-Taiwan |

| 7 | Sensor / Encoder | Omron-Nyiv |

| 8 | Hloov | Schneider-Fabkis |

| PNEUMATIC COMPONENTS | ||

| 1 | Yam khoom | Airtac-Taiwan |

| BEARING | ||

| 1 | Main bearing | NSK-Japan |

①Kev kub ceev tsis nres feeder:

4 suckers rau nqa daim ntawv thiab 4 suckers rau conveying ntawv kom ruaj khov thiab ceev ntawv pub. Max. pub ceev 12,000 daim / h.

Kev kub ceev feeder

Kev thauj ntawv ruaj khov

Tsis Siv Neeg Sab Qhia Khaws qhov sib tshooj ≤ ± 2mm

②Laminating Unit:

E qauv nrog loj Dia. 800mm ntawm lub tshuab ziab khaub ncaws thiab lub qhov cub pabcuam rau lub tshuab ziab khaub ncaws ceev.

Electromagnetic cua sov system (tsuas yog cua sov rau cov menyuam)

Qhov zoo: cua sov ceev, lub neej ntev; nyab xeeb thiab txhim khu kev qha; efficiency thiab txuag hluav taws xob; tswj qhov kub thiab txias; rwb thaiv tsev zoo; txhim kho ib puag ncig ua haujlwm.

Electromagnetic cua sov tus tswj Laminating unit tsav saw saws txais los ntawm Taiwan.

Pab Kom Qhuav Cub Glue txheej thiab kua nplaum ntsuas cov menyuam nrog tuab Chromium plating kho

High precision txheej lub ntsiab lub cev muaj zog

Ntxiv zaj duab xis txiav thiab winding ntaus ntawv

Daim ntawv so sensor, lub tshuab pub mis luv yuav nres, qhov ua haujlwm no zoo kom tsis txhob yob qias neeg los ntawm cov kua nplaum.Lub tshuab ua haujlwm los ntawm, kev ua haujlwm yooj yim los ntawm ib tus neeg teb xov tooj.

Lub tshuab ua haujlwm los ntawm, kev ua haujlwm yooj yim los ntawm ib tus neeg teb xov tooj.

③Round riam

Round riam txiav tuaj yeem siv rau ntau tshaj 100 grams ntawv, ntau lawm ntawm 100 grams ntawv yuav tsum tsim nyog txo qis. Xyuas kom daim ntawv tiaj tus tom qab txiav. Cov yoov tawm riam nrog 4 hniav, kev sib hloov bidirectional, ceev synchronization nrog lub tshuab loj, kuj tuaj yeem kho qhov sib piv ceev. Nrog rau kev taw qhia log qauv, daws qhov teeb meem ntawm zaj duab xis ntug.

Daim ntawv xa khoom Pneumatic txais yuav Taiwan Airtac.

Round riam txiav thiab Bounce yob ntaus ntawv.

④riam kub thiab puag ncig riam

Txiav mechanism 1: Rotary fly-cutter txiav tshuab.

Rotary riam txiav tuaj yeem siv rau ntau tshaj 100 grams ntawv, ntau lawm ntawm 100 grams ntawv yuav tsum tsim nyog txo qis. Xyuas kom daim ntawv tiaj tus tom qab txiav. Cov yoov tawm riam nrog 4 hniav, kev sib hloov bidirectional, ceev synchronization nrog lub tshuab loj, kuj tuaj yeem kho qhov sib piv ceev. Nrog rau kev taw qhia log qauv, daws qhov teeb meem ntawm zaj duab xis ntug.

Txiav mechanism: saw riam mechanism. (OPTIONAL)

Cov saw riam thiab kub riam txiav tshwj xeeb rau txiav cov ntawv nyias uas laminated rau PET zaj duab xis, Nws yog tsim rau txiav BOPP, OPP zaj duab xis.

PET zaj duab xis nrog lub zog adhesion thiab muaj kev tiv thaiv kev ua haujlwm ntau dua li cov yeeb yaj kiab, saw riam yooj yim los txiav PET zaj duab xis, yog li muaj txiaj ntsig zoo rau kev ua tiav tom qab, txo qis zog, lub sijhawm thiab cov khoom pov tseg tsis zoo, yog li txo tus nqi, nws yog tus pab zoo. rau daim ntawv txiav. Cov cuab yeej saw tswj los ntawm servo lub cev muaj zog ntawm nws tus kheej, nws yooj yim ua haujlwm thiab txij nkawm.

Txiav mechanism: kub riam mechanism. (OPTIONAL)

Kev sib hloov riam tuav.

Cua sov riam ntug ncaj qha, ua haujlwm nrog kev nyab xeeb tsawg voltage 24v, ceev cua sov thiab cua txias.

Sensor, rhiab nrhiav pom ntawm daim ntawv thickness hloov, yog txiav txim siab txoj hauj lwm ntawm daim ntawv txiav.

Display.Hot riam txiav ua kom muaj qhov sib txawv ntawm qhov kub thiab txias, raws li cov ntawv sib txawv thiab qhov ntev, txhawm rau ua kom zoo txiav.

Encoder Kub riam txoj hauj lwm sensor (saib daim ntawv thickness: kuj haum rau kub thiab nyiaj cardboard.)

⑤Tsis-stop collector unit

Lub tshuab tsis siv neeg sau ntawv tsis siv neeg lub tshuab laminating muaj lub luag haujlwm ntawm kev sau ntawv tsis raug kaw; qhov sib sau ua ke yog txuam nrog cov ntawv feeder.

Film lifter

Cov khoom seem

| Tsis muaj. | Lub npe | Hom | Keeb kwm |

| 1 | Main lub cev muaj zog | Bolilai | Zhejiang |

| 2 | Feeder | Runze | Zhuji |

| 3 | Lub tshuab nqus tsev twj | Tongyou | Jiangsu |

| 4 | Cov kabmob | NSK | Nyiv |

| 5 | Zaus converter | Delta | Taiwan |

| 6 | Ntsuab tiaj khawm | Schneider | Fabkis |

| 7 | Liab tiaj khawm | Schneider | Fabkis |

| 8 | Scram khawm | Schneider | Fabkis |

| 9 | Rotary pob qhov rooj | Schneider | Fabkis |

| 10 | AC contactor | Schneider | Fabkis |

| 11 | Servo lub cev muaj zog | Weikeda | Shenzhen |

| 12 | Servo tsav tsheb | Weikeda | Shenzhen |

| 13 | Servo txo iav | Taiyi | Shanghai |

| 14 | Hloov fais fab | Delta | Taiwan |

| 15 | Kub module | Delta | Taiwan |

| 16 | Programmable logic maub los | Delta | Taiwan |

| 17 | Nres tsis kam | Delta | Taiwan |

| 18 | Lub tog raj kheej | AIRTAC | Shanghai |

| 19 | Electromagnetic valve | AIRTAC | Shanghai |

| 20 | Kov npo | Xiankong | Shenzhen |

| 21 | Breaker | CHNT | Wenzhou |

| 22 | Hydraulic twj tso kua mis | Tiandi Hydraulic | Ningbo |

| 23 | Cov saw | KMC | Hangzhou |

| 24 | Conveyor siv | Hulong | Wenzhou |

| 25 | Ib-txoj kev pneumatic diaphragm twj tso kua mis | FAZER | Wenzhou |

| 26 | Draft fan | Yinniu | Taizhou |

| 27 | Encoder | Omron | Nyiv |

| 28 | Rolling lub cev muaj zog | Shanghe | Shanghai |

| 29 | Chain riam Sensor | microsonic | Lub teb chaws Yelemees |

| 30 | Chain riam servo-Option | Weikeda | Shenzhen |

| 31 | Chain riam kov screen-Option | Weinview | Taiwan |

| 32 | Kub riam servo-xaiv | Keyence | Nyiv |

| 33 | Kub riam servo-xaiv | Weikeda | Shenzhen |

| 34 | Kub riam kov npo - xaiv | Weinview | Taiwan |

Nco tseg: cov duab thiab cov ntaub ntawv rau kev siv nkaus xwb, hloov pauv yam tsis tau ceeb toom.

Ib qho kev hloov pauv tso zis:

BOPP zaj duab xis nrog cov ntawv dawb zoo tib yam 9500 nplooj / h (raws li daim ntawv quarto).

Tus naj npawb ntawm cov neeg ua haujlwm:

Ib tus neeg ua haujlwm tseem ceeb thiab ib tus neeg pabcuam pabcuam.

Yog tias tus neeg siv yuav tsum pib ua haujlwm ob zaug ib hnub, txhua txoj haujlwm nce ib tus neeg ua haujlwm.

Kua nplaum thiab zaj duab xis:

Feem ntau khaws cia rau cov kua nplaum los yog zaj duab xis tsis pub ntau tshaj 6 lub hlis; Cov kua nplaum qhuav zoo tom qab txheej txheem laminating, nws yuav ua kom lub laminating zoo ruaj khov.

Dej raws li cov kua nplaum, raws li cov ntsiab lus ntawm cov khoom sib txawv ntawm tus nqi, cov ntsiab lus khoom yog siab, tus nqi kim dua.

Gloss thiab lev zaj duab xis, raws li cov khoom yuav tsum tau, feem ntau yog siv 10, 12 thiab 15 micrometer, films thicker tus nqi siab dua; Thermal (Pre-coated) zaj duab xis, raws li zaj duab xis thickness thiab EVA txheej faib, feem ntau siv 1206, zaj duab xis thickness 12 micrometer, EVA txheej 6 micrometer, tuaj yeem siv rau feem ntau laminating, yog tias xav tau tshwj xeeb xav tau rau cov khoom sib sib zog nqus embossed, qhia. siv lwm hom pre-coat zaj duab xis, xws li 1208, 1508 thiab lwm yam, thiab tus nqi sib npaug.

Marketing & Technical Service CenterTechnical Training Professional operating engineers xa los ntawm GREAT yog lub luag haujlwm rau cov khoom siv installation thiab commissioning ua haujlwm tib lub sijhawm, kev cob qhia rau cov neeg siv khoom.

Tus neeg siv khoom yuav tsum tau ris nws daim Visa, daim pib mus ncig, tag nrho chav mus ncig thiab lub nkoj thiab them nyiaj 100.00 USD ib hnub.

Cov ntsiab lus qhia:

Tag nrho cov tshuab tau ua tiav tag nrho cov kev hloov kho thiab kev sim hauv GREAT Rhiav ua ntej xa khoom, cov qauv siv tshuab, cov khoom hloov kho, hluav taws xob ua haujlwm ntawm kev hloov, thiab cov teeb meem xav tau kev saib xyuas, kev tu txhua hnub ntawm cov khoom siv, thiab lwm yam., txhawm rau xyuas kom meej kev ua haujlwm ntawm cov khoom siv ib txwm muaj, tom qab ntawd.

Warranty:

13 lub hlis rau cov khoom siv hluav taws xob, kev pabcuam yog rau tag nrho lub neej, ib zaug koj nug cov khoom seem, peb tuaj yeem xa tam sim, cov neeg siv khoom them tus nqi xa khoom. (Txij li hnub ntawm kev yuav khoom los ntawm kev xa khoom thiab ntawm lub rooj tsavxwm, hauv 13 lub hlis)

Lub tuam txhab hwm

Chaw thau khoom thiab ntim khoom

Rhiav

Lub Hoobkas luv