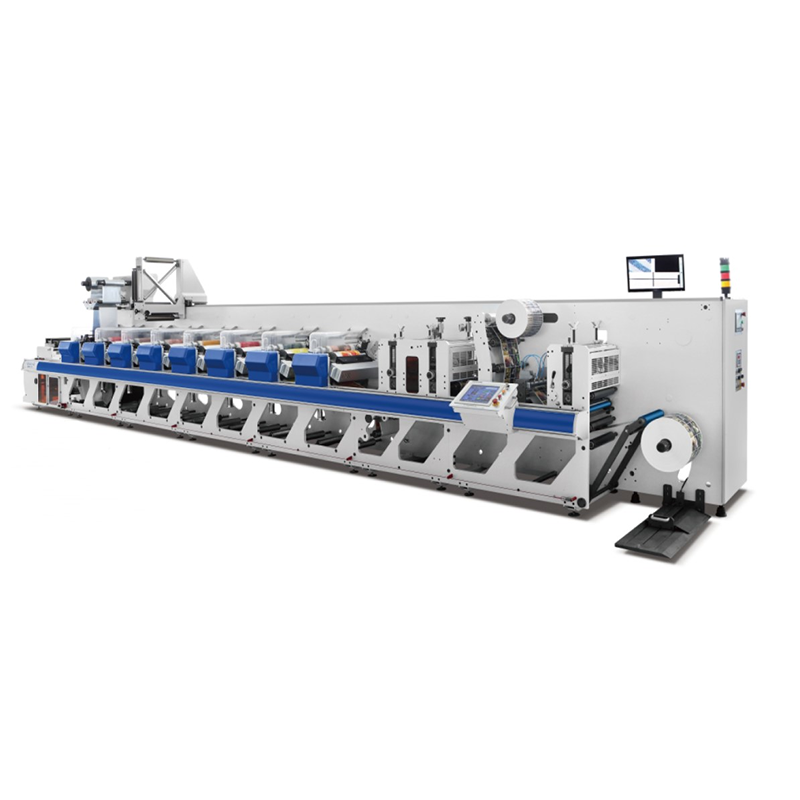

ZJR-450G LABEL FLEXO tshuab luam ntawv

CHARACTERISTIC

1. Lub tshuab tag nrho txais qhov tseeb servo tswj qhov systemSiemenslos ntawm lub teb chaws Yelemees thiab txhua lub luam ntawv

Chav tsev yog tsav los ntawm ywj siab servo lub cev muaj zog. Muaj17servomotors nyob rau hauv tag nrho rau7ximstshuab uas xyuas kom meej qhov kev sau npe khiav ntawm kev kub ceev.

2. Cov menyuam luam ntawv txais lub tes tsho uas yog lub teeb, yooj yim, yooj yim thiab ceev hloov. Qhov kev tsim no feem ntau txhim kho kev luam ntawv zoo thiab txo cov txij nkawm.

3. Ceev thiab yooj yim hloov siab ntawm luam ntawv lossis number case hloov: luam ntawv cov menyuam khiav los ntawm tus tuav. Nws tsis yog

tsim nyog los kho lub siab thaum hloov cov menyuam, lossis feem ntau zoo kho rau txoj haujlwm tshwj xeeb.

4. Anvil roller equips nrog dej chiller, nws yog qhov zoo rau cov khoom siv zaj duab xis thiab

Khoom siv SUBSTRATE

Daim ntawv thiab daim ntawv nplaum: 20 mus rau 500 Grams

Bopp, Opp, PET, PP, Lub Tes Tsho Shink, IML, thiab lwm yam, feem ntau yas zaj duab xis. (12 micron - 500 micron)

MAIN TECHNICAL SPECIFICATION

| Qauv | Qauv Zauv: ZJR-450G |

| Max Printing Ceev | 180m / min |

| Xim luam ntawv | 7xim |

| Max. Davof Daim ntawv | 4 70mm |

| Max .Printing dav | 450 hli |

| Max. Unwinding Txoj kab uas hla | 900 hli |

| Max. Rewinding Diameter | 900 hli |

| Luam Length | Z76-Z192 (241.3mm-609.6 hli) |

| Dimensions (8Colus+3Die Txiav) | 10.83m x 1.68mx 1.52m (L x W x H) |

MACHINE DUAB:

3) Movable Tig Bar

4) Movable Touch Screen

5) Matrix Unit (nrog rau kev tuag txiav) + Sib Nqus Cov Menyuam Lifter

Tshuab Configuration:

Nws Pib Tswj System

-Qhov tseebSiemenstswj qhov system

-Kev ua haujlwm ua lus Askiv thiab Suav

- Sau npe Senor (P + F)

- Tsis siv neeg qhov yuam kev thiab lub tswb system

-BST Video tshuaj xyuas qhov system (4000type)

Lub hwj chim: 380V-400V, 3P, 50HZ-60HZ

Khoom noj khoom haus System

-Unwinder nrog pneumatic nqa (Max. txoj kab uas hla: 900mm)

- Cua ncej (3 nti)

- Tsis siv neeg inflated thiab deflated

- Pneumatic rotaing sib koom

-Magnetic hmoov nres

- Tsis siv neeg nro tswj

- Tsis siv neeg nres qhov system kom tsis muaj cov khoom siv

-RE web guiding system

-Nyob los ntawm servo lub cev muaj zog (Siemensservo lub cev muaj zog)

Printing System

- Super flexo luam ntawv chav tsev

-Printing lub tog raj kheej yog tswj los ntawm kev ywj pheej ncaj qha tsav lub cev muaj zog (kom tsis txhob muaj cov cim iav)

-Printing lub tog raj kheej nrog lub tes tsho, yog lub teeb thiab hloov tau yooj yim.

-Printing phaj: daim hlau mounted ntawm lub tes tsho

-Dawb impression roller thiab dej chiller roller.

- Dej chiller cov menyuam uas tau tsav los ntawm kev ywj pheej servo lub cev muaj zog thiab nws tuaj yeem luam cov yas zaj duab xis zoo.

- Tsis siv neeg txias circulatory system

-Dawb impression roller thiab dej chiller yog tsim los ntawm kev sib cais, txawm tias tus number case khiav hauv lub siab nyiam cov menyuam, nws tuaj yeem yooj yim los ntxuav vim tsis muaj uv curing.

-Txhua luam ntawvunit muajob lub servo lub cev muaj zogtswj.

Servo 1 tswj lub tes tsho Printing, thiab Servo 2 tswj lub tshuab chiller loj.

- Kev sau npe ua ntejyog tswj los ntawm servo lub cev muaj zog, thiab lub cev muaj zog yuav xam txiav txim siab thaum koj nkag mus rau qhov luam ntawv ntev nyob rau hauv lub ntsiab kov npo. lub tes tsho luam ntawv yuav mus rau qhov chaw sib thooj ntawm lub xoom taw tes ntawm lub tes tsho.

- Kev sau npe zooyuav tsum tau kho ntawm lub vijtsam kov

Thaum koj ua qhov tseeb xim sau npe, ces qhib lub register sensor nyeem cov ntawv luam ntawv thiab lub tshuab tuaj yeem ua tsis siv neeg sau npe ib txwm.

-Kev ua haujlwm vaj huam sib luag rau kev kho kom zoo nrog rau kev ntsuas tus kheej

-Fine pressure adjustment rau tus tuav

-Lub siab ntawm cov menyuam anilox, cov ntawv luam ntawv thiab cov khoom yuav raug kho zoo los ntawm dais uas

Tswj los ntawm lub cev muaj zog me me. nws tuaj yeem ua haujlwm tau yooj yim los ntawm tus yuam sij txuas.

- Second Pass los ntawm kev sau npe sensor (P + F)

- Yooj yim tshem tawm anilox roller

- Yooj yim tak-off number case tais, nws pib nce / nqis

-Movable touch screen (kev ua haujlwm yooj yim)

-Txoj kab rau tag nrho lub tshuab (Schneider-Fabkis)

UV tshuab ziab khaub ncaws (Ntxuam txias 9KW ib chav tsev)

-UV Ray hom los ntawm ltalis, Stepless hluav taws xob UV

-Kev tswj fais fab ywj pheej rau txhua lub tshuab ziab khaub ncaws UV

-Power pib hloov raws li kev luam ntawv ceev

- Nws pib tswj nrog UV tso pa tawm

-Independent UV tswj vaj huam sib luag

Rewinding System

- Tsav los ntawm kev ywj pheej servo lub cev muaj zog (3 nti cua ncej)

- Ob chav rewinder rau kev xaiv

- Tsis siv neeg inflated thiab deflated

-SMC Pneumatic tig

-RE tsis siv neeg nro tswj qhov system

-Rewinder nrog pneumatic nqa (Max. txoj kab uas hla: 900mm)

Main Configuration

| ● TSEEM CEEB SYSTEM | |||

| Kev piav qhia | Nco tseg | Ntau | Hom Lub Npe |

| Computer Control System | Multi-Axis Control System | 1 | Siemens(Lub teb chaws Yelemees) |

| PLC | 1 | Siemens(Lub teb chaws Yelemees) | |

| PLC Extending Module | 1 | Siemens(Lub teb chaws Yelemees) | |

| Analog Module | 1 | Siemens(Lub teb chaws Yelemees) | |

| Kov Screen rau Main Tshuab | Xim tiag | 1 | Siemens(Lub teb chaws Yelemees) |

| Chaw taws teeb IO Module | 1 | Phoenix (Lub teb chaws Yelemees) | |

| Cua Hloov | 1 | Schneider (Fabkis) | |

| Hloov / khawm | 8 | Schneider (Fabkis) | |

| Contactor | 5 | Schneider (Fabkis) | |

| Switching Power Supply | 1 | Meanwell (Taiwan) | |

| Aviation Plug&Terminal Thaiv | 6 | SIB | |

| ● Txhua lub PRINTING UNIT | |||

| Kev piav qhia | Nco tseg | Ntau | Hom Lub Npe |

| Dej Chiller Cov Menyuam Servo Tsav | 1 | Siemens(Lub teb chaws Yelemees) | |

| Dej Chiller Cov Menyuam Servo Tsav | 1 | Siemens(Lub teb chaws Yelemees) | |

| Printing Form Roller Servo Tsav | 1 | Siemens(Lub teb chaws Yelemees) | |

| Printing Form Roller Servo Tsav | 1 | Siemens(Lub teb chaws Yelemees) | |

| Tshwj xeeb Decelerator | 1 | SH1MPO-ABLE (Nyiv) | |

| Limit Hloov | 8 | Schneider (Fabkis) | |

| Txoj Kev Coj Ncaj Ncees | 4 | PMI (Taiwan) | |

| Lub tog raj kheej | 14 | SMC (Nyiv) | |

| href="#/javascript:;" SolenoidValve | 10 | SMC (Nyiv) | |

| ● WEB-PASSING SYSTEM | |||

| Kev piav qhia | Nco tseg | Ntau | Hom Lub Npe |

| Servo Tsav | 3 KW | 2 | Siemens(Lub teb chaws Yelemees) |

| Servo Tsav Tsav Tsheb | 2 | Siemens(Lub teb chaws Yelemees) | |

| Tshwj xeeb decelerator | 2 | SH1MPO-ABLE (Nyiv) | |

| Photocell rau qhov kawg yob | 1 | Schneider (Fabkis) | |

| ● REWINDER SYSTEM | |||

| Kev piav qhia | Nco tseg | Ntau | Hom Lub Npe |

| Servo Tsav | 1 | Siemens(Lub teb chaws Yelemees) | |

| Sensor | 1 | RE – Italia | |

| Hloov | Ob peb | Schneider (Fabkis) | |

| ● UNWINDER SYSTEM | |||

| Kev piav qhia | Nco tseg | Ntau | Hom Lub Npe |

| Ultrasonic web guider | 1 | RE – Italia | |

| Magnetic hmoov khoom | 1 | RE – Italia | |

| Sensor | 1 | RE – Italia | |

| Hloov | Ob peb | Schneider (Fabkis) | |

| ● LWM SYSTEM | |||

| Kev piav qhia | Nco tseg | Ntau | Hom Lub Npe |

| UV tshuab ziab khaub ncaws |

| 1 TSI | UV Ray-Italy |

| Video System |

| 1 TSI | BST (Lub teb chaws Yelemees) |

Tshuab hauv peb lub rooj cob qhia:

Peb lub Hoobkas CNC

Qee cov qauv luam ntawv: