Tsis Siv Neeg Folder Gluer rau corrugated thawv (JHX-2600B2-2)

| Qauv | JHX-2600B2-2 |

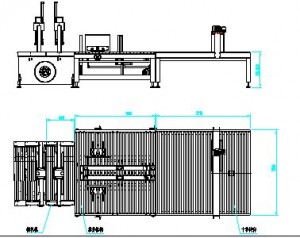

| Qhov chaw teeb tsa | 12000 * 4200 hli |

| Tag Nrho Lub Zog | 14.1 KWG |

| Max.Gluing Ceev | 130m / min |

| Daim Ntawv Thickness | A, B, C, AB |

| Txoj Kev Gluing | Glue Log |

| Gluing Dav | 25/35 hli |

| Fais fab mov | 380V 50Hz |

Thaum twg gluing

| Qauv | JHXDX-2600B2-2 | |

|

| Max (mm) | Min (mm) |

| A | 880 ua | 200 |

| B | 900 | 100 |

| C | 880 ua | 200 |

| D | 900 | 100 |

| E | 2500 | 680 |

| F | 900 | 300 |

| G | 35-40 : kuv | |

a)Ntsiab nta

● Cov ntawv sib cais tshwj xeeb thiab cov ntawv sau npe uas tuaj yeem tshem tawm cov ntsesTail phenomenon zoo.

● Kev txiav txim txuag muaj nuj nqi tuaj yeem khaws cov thawv loj hauv lub vijtsam kov, lub tshuab yuav hloov kho tau thaum tus neeg teb xov tooj xaiv qhov kev txiav txim khaws tseg.

b)Lub ntsiab nta

● Patent tsim ntawm 90 ° lub kaum sab xis folding riam tuaj yeem ua rau lub thawv folding precisely.

●Siv lub cev muaj zog los kho cov hlua khi synchronous, ua haujlwm yooj yim thiab txo lub sijhawm hloov.

●

Pub Unit:

a) Txais cov khoom siv roj hmab zoo zoo, cov khoom siv thiab cov khoom siv tsis siv neeg los xyuas kom meej qhov ua tau zoo ntawm kev pub mis.

b) Kev tsim tshwj xeeb ua rau kev hloov pauv yooj yim, sai thiab meej.Pneumatic sab kev cai, ntawv pub baffle thiab siv tau cais ua haujlwm, uas ua rau kev txiav txim hloov tau yooj yim.

Creasing lub log

Muaj lub log creasing ntawm qhov taw tes, thiab cov nyhuv folding zoo dua.

Gluing Unit:

a) Qhov dav gluing yog 25mm / 35mm-gluing los ntawm sab hauv qab.

b) Lub thawv nplaum tuaj yeem txav mus rau sab laug lossis sab xis raws li qhov yuav tsum tau ua ntawm corrugated board.

c) Tus nqi gluing tuaj yeem hloov kho.

d) Lub thawv nplaum yog ua los ntawm cov hlau tsis muaj steel-loj muaj thiab yooj yim rau kev ntxuav.

e) Cov txheej txheem tswj hluav taws xob ua rau cov ntsia hlau stitching ntau meej.

f) Tsis siv neeg ntsia thawv pub khoom noj, plaub lub sensors ntes tus ntsia thawv tsis txaus.

Cov menyuam siab

Xya lub siab chais los ntawm loj mus rau me me, nws tsis yooj yim rau crushed daim ntawv thiab xyuas kom meej cov nyhuv folding zoo.

Folding Unit

a) Nws siv txoj siv tawv nruj.Lub folding ceev yog tswj los ntawm zaus converter uas yuav tswj tau nyias thiab synchronized nrog lub ntsiab lub cev muaj zog.

b) Tsav tsav rau kev txiav txim hloov kho-ceev thiab yooj yim.

c) Re-creasing roller, re-creasing riam, side roller thiab flapping phaj tuaj yeem tshem tawm cov ntses tail zoo.Lub riam rov tsim dua tshiab tsim thiab qauv uas ua rau lub thawv folding ncaj thiab zoo meej.

d) Sab saum toj ntxiv dag zog qhov chaw txais cov liner swb tsheb ciav hlau thiab pneumatic ntsuas pneumatic, nws ua rau lub tshuab khiav ruaj khov hauv kev kub ceev uas tuaj yeem ua kom lub folding precisely.

Diagonal siab roller

Muaj ib txheej kab pheeb ces kaum siab rau sab nraum qab ntawm sab laug folding thiab txoj cai folding uas tuaj yeem ua tiav 90 degree folding.

Sheet Separation and Registration Unit

a) Peb cov qauv tsim tshwj xeeb ntawm daim ntawv sab nteg thiab nrawm qhov sib txawv tuaj yeem txuas nrog lwm cov ntaub ntawv tsis siv neeg nplaum.

b) Thaum xaiv hom stitching, muaj ob lub servo motors tswj cov ntawv sib dhos ua haujlwm, cov nyiaj them rov qab thiab kho qhov system tshem tawm cov ntses tails tshwm sim.

Tsis Siv Neeg Kho Kev Ua Haujlwm

Rov tsim thiab cov qauv ntawm kev txhawb nqa log, kev tswj hluav taws xob thiab kev tsav tsheb ua rau kev hloov kho sai thiab yooj yim, haum rau cov thickness corrugated sib txawv.

Siv rau sab saum toj ntawm daim ntawv corrugated raws li cov kab hauv paus tau txais qhov tseeb qhov chaw thiab txo cov teeb meem ntses ntses loj heev.

Lub cev muaj zog thiab encoder ua rau kev hloov pauv yooj yim thiab yooj yim, tus neeg teb xov tooj tuaj yeem txuag cov ntaub ntawv txawm tias kov npo.

Stitching Unit

1.Adopts Synchronous siv tsav, PLC tswj qhov system, kov npo hloov, yooj yim, ceev thiab raug.

2.Lub viav vias style stitching lub taub hau nrog cov yam ntxwv ntawm kev siv hluav taws xob tsawg, kev ceev ceev thiab kev ruaj ntseg siab tuaj yeem txhim kho cov khoom zoo.

3.One khawm tswj lub gluing hom thiab stitching hom pauv, tag nrho cov kev hloov kho tswj los ntawm hluav taws xob lub cev muaj zog.

4.Cov ntsia hlau pitch thiab stitching taub hau nce thiab nqis yog tswj los ntawm hluav taws xob motors.Cov riam txiav tau txais cov khoom siv cemented carbide, lub neej ua haujlwm ntev.

5.Tus ntsia thawv zoo tuaj yeem hloov kho raws li daim ntawv yuav tsum tau ua.

Stacking thiab suav Unit

a) Flapping Phaj tuaj yeem pab txo cov ntses tail tshwm sim thaum gluing.

b) Tus lej pawg tuaj yeem teeb tsa ntawm 10, 15, 20 thiab 25.

Kev tshawb fawb thiab tsim nyog txhua yam qauv, txhim khu kev qha zoo hluav taws xob ua rau lub tshuab tsis muaj teeb meem.

1.Installation cheeb tsam: 12000 × 4200mm

2.Kev cob qhia, kev teeb tsa thiab kev debugging

a) Tus neeg muag khoom them tus nqi ntawm kev teeb tsa, kev debugging thiab kev cob qhia hauv tus neeg yuav khoom lub Hoobkas.Txawm li cas los xij cov hnub siv yuav tsum tsis pub ntau tshaj xya hnub

b) Tus neeg yuav khoom yuav tsum sim pab ntau npaum li lawv tuaj yeem ua tau thaum tus neeg muag khoom tus kws ua haujlwm tau debugging lub tshuab los ntawm kev muab cov neeg ua haujlwm txaus, lub zog, cov cuab yeej thiab qee cov ntaub ntawv tsim nyog lossis cov ntaub ntawv.

a)Hluav taws xob qhov chaw:

| Lub npe | Hom | Specification | Qauv | Ntau |

| Zaus converter | Invoance |

| MD 300 | 1 |

| Hwj chim | Taiwan txhais tau tias zoo | S-150-24 | NES-150-24 | 1 |

| Contactor | Fabkis Schneider | LC1-D0910M5C | LCE0910M5N | 5 |

| Tswj khawm | Shanghai Tianyi | Ntsuab khawm | LA42P-10 | 13 |

| Liab khawm | Qauv: LA42PD-01 | 1 | ||

| Lub teeb ntsuab | LA42PD-10 / DC 24V | 4 | ||

| Lub teeb liab | LA42PD-01 / DC 24V | 4 | ||

| Lub teeb daj | LA42PD-20 / DC 24V | 1 | ||

| Tswj pob qhov rooj | Fuji |

| Txa42J-01 | 1 |

| Photoelectric hloov | OPTEX |

| BTS-10 N | 1 |

| Cua hloov | Delixi | DZ47 | E3F3-D11 | 1 |

| Kov npo | Hitech | 10 nti | PWS 5610T-SB | 1 |

| PLC | Invoance |

|

|

|

b)Main Mechanical Parts:

|

| Lub npe | Hom | Ntau |

| 1 | Pub siv (A) | Bailite | 6 |

| 2 | Txais siv (C) | Forbo-siegling | 19 |

| 3 | Conveyor siv (B) | Forbo-siegling | 13 |

| 4 | Cua ntxuam | Hengshui (Daim ntawv tso cai) | 1 |

| 5 | Main Tsav | Simens (zeeg) | 1 |

| 6 | Gear Tsav | Zhejiang | 6 |

-Sample-300x260.jpg)