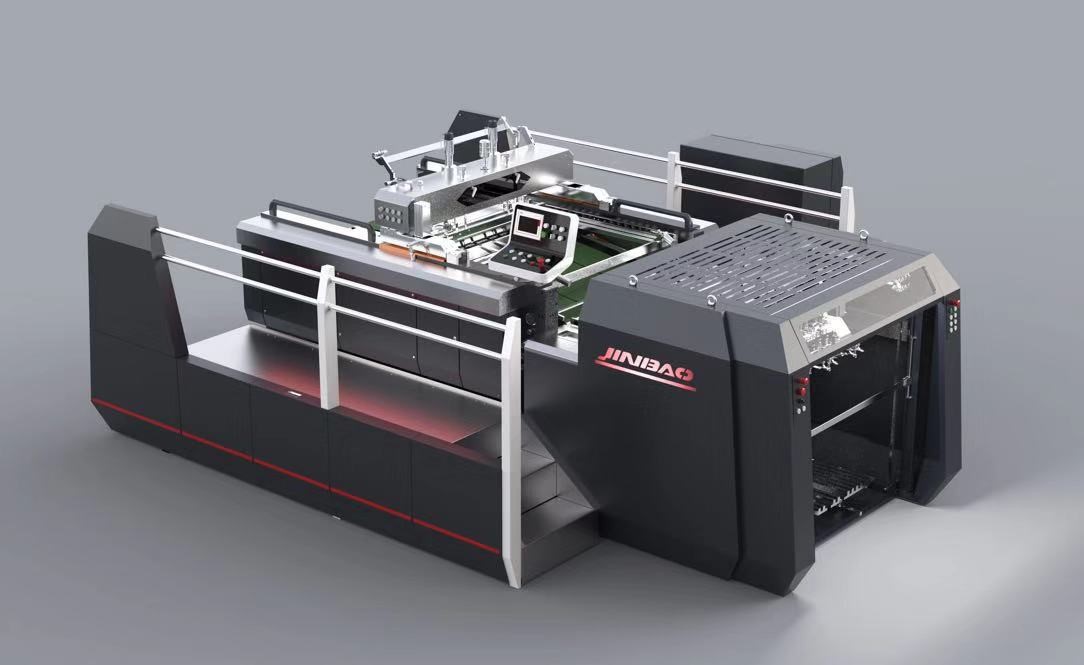

JB-106AS Servo Tsav Tswj Tsis Siv Neeg Nres Lub tog raj kheej Screen Xovxwm

| JB-106 AS | |

| Max.daim ntawv loj | 1060 × 750 m² |

| Min.daim ntawv loj | 560 × 350 ㎜² ua tau |

| Max.luam ntawv loj | 1050 × 750 m² |

| Ncej loj | 1300 × 1170 hli |

| Thickness ntawm daim ntawv | 80-500 g / m² |

| Ciam teb | ≤10mm |

| Kev luam ntawv ceev | 800-5000 daim / h |

| Installation zog | 3P 380V 50Hz 24.3Kw |

| Tag nrho qhov hnyav | 4600 ㎏ |

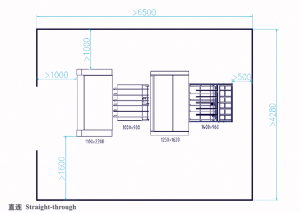

| Zuag qhia tag nrho | 4850 × 4220 × 2050 hli |

1. Daim ntawv pub pub mis: offset Feida taub hau, siab dua, kev ntseeg siab thiab ruaj khov.

Nws muaj zog adaptability rau cov tuab ntawm cov ntawv luam tawm, thiab xyuas kom meej cov ntawv pub mis ntawm kev kub ceev;

Daim ntawv pub tuaj yeem xaiv los ntawm nws tus kheej thiab hloov ib daim ntawv lossis laminated ntawv los ntawm ib lub pob.

2. Daim ntawv pub mis:

Lub rooj noj mov stainless hlau tuaj yeem tiv thaiv lub nraub qaum ntawm substrate los ntawm khawb, thiab txo qhov kev sib txhuam zoo li qub ntawm lub rooj thiab substrate;

Nrog lub tshuab nqus tsev adsorption nyob rau hauv qab ntawm lub rooj, nrog rau cov qauv ntawm kev thawb ntawv thiab nias daim ntawv ntawm lub rooj, kom ntseeg tau tias kev thauj mus los ntawm ntau yam khoom;

Thaum ib daim ntawv pub noj, txoj siv conveyor qeeb qeeb ntawm lub sijhawm kom ntseeg tau tias lub substrate ruaj khov thiab nyob rau hauv qhov chaw ntawm kev kub ceev.

3. Pneumatic sab ntsuas:

Lub downward suction lub tshuab nqus tsev sab rub ntsuas yuav tsis ua rau cov ntawv dawb thiab qias neeg thiab cov ntawv cim;

Ib lub cev hloov pauv hloov pauv lub ntsuas ntsuas, ib qho kev hloov pauv tseem ceeb, pib thiab tswj lub ntsuas ntsuas rub lub ntsuas ntsuas hloov pauv;

Push rub positioning yog qhov tseeb, positioning stroke ntev, positioning ceev ceev, thiab kev hloov yog yooj yim.Lub photoelectric nrhiav kom tau qhov system tuaj yeem saib xyuas txoj haujlwm ntawm cov khoom luam tawm hauv lub sijhawm tiag tiag thiab txo tus nqi luam ntawv pov tseg.

4. Shaftless system: ib txwm siv fais fab ntawm lub ntsiab tsav nrog ntau hom tsav

Siv tshuab synchronous tsav tsheb, lub tshuab xa hluav taws xob, gearbox thiab lwm yam khoom siv tshuab raug tshem tawm, thiab ntau lub servo motors tau siv los ua raws li lub tshuab hluav taws xob virtual.Ntau tus neeg kho tshuab kis tau tus mob tau raug tshem tawm.

Lub suab nrov txo: cov tsoos lub ntsiab ncej thiab lub gearbox raug muab pov tseg, qhov txav txav tau txo qis, cov qauv siv tshuab tau yooj yim, thiab cov khoom tsim cov tshuab kev vibration raug txo, yog li lub suab nrov txo qis hauv cov txheej txheem ua haujlwm..

5. Heavy pneumatic scraping system: daim ntawv thov kev siv hluav taws xob, pneumatic, hydraulic tshuab, tsis siv neeg tswj kev ua haujlwm scraping;

Pib thiab xaus cov ntsiab lus tuaj yeem teeb tsa ntawm nws tus kheej;

Tag nrho cov txheej txheem siab yog sib npaug thiab ruaj khov;

Tom qab sib tsoo lub scraper los yog hloov nws nrog ib tug tshiab, nias ib tug yuam sij los teem thiab rov qab tau lub yav dhau los printing siab txoj hauj lwm;

Nws tag nrho tshem tawm qhov tsis zoo ntawm cam mechanical control of squeegee action, thiab xyuas kom meej tias cov number case txheej thiab clarity ntawm daim duab yog ruaj khov nyob rau hauv tej ntim thiab luam ntawv ceev.

6. Screen sib cais muaj nuj nqi:

Lub vijtsam yog cais los ntawm kev tswj hluav taws xob kom nthuav tawm tag nrho cov lus conveying thiab cov menyuam, thiaj li ua kom yooj yim rau kev sau npe ntawm cov ntawv luam tawm thiab kev hloov pauv ntawm cov khoom noj;nyob rau tib lub sijhawm, kev tu cov menyuam thiab cov tshuaj ntsuam muaj kev nyab xeeb thiab nrawm dua;

7. Hluav taws xob tshuaj ntsuam zoo-tuning system, tej thaj chaw deb hluav taws xob tshuaj ntsuam peb-axis hloov, ncaj qha kev hloov kho stroke, ib kauj ruam hloov nyob rau hauv qhov chaw, yooj yim thiab tswv yim.

8. Tsis siv neeg roj thiab lubricating system tuaj yeem txo cov saw rub thiab suab nrov, thiab ua kom cov haujlwm raug thiab ruaj khov.

| Yam khoom | Kev qhia | |||

| 1 | Feeder |

| ||

|

| ● | Rov qab nqa offset version feeder taub hau | Plaub nqus plaub tus me nyuam, nrog kev kho qhov chaw ua ntej | txheem |

| ● | Ob chav hom ntawv pub hom | ib daim ntawv (hloov pauv ceev daim ntawv pub) los yog sib tshooj (cov ntawv ceev ceev pub mis) | txheem | |

| ● | Hloov ceev ntawm daim ntawv pub hom | ib qho tseem ceeb hloov | txheem | |

| ● | Photoelectric ob chav kuaj pom | txheem | ||

| ● | Ultrasonic ob daim ntawv nrhiav kom tau | tsuas yog siv tau rau ib daim ntawv ntawv pub hom | xaiv tau | |

| ● | Ib tus yuam sij hloov qhov loj ntawm daim ntawv | lub taub hau feeder thiab sab gauge nres ntawv nyob rau hauv qhov chaw sai thiab txiav | txheem | |

| ● | Kev nyab xeeb txwv rau feeder lifting | txheem | ||

| ● | Standard configuration ntawm non-stop system | txheem | ||

| ● | Kev thauj khoom ua ntej | stacking cov ntaub ntawv ua ntej, txo lub sij hawm stacking thiab txhim kho kev ua hauj lwm efficiency | xaiv tau | |

| ● | Kev tshem tawm hluav taws xob zoo li qub | tuaj yeem txo cov hluav taws xob zoo li qub ntawm cov khoom siv saum npoo thiab txhim kho cov nyhuv luam ntawv | xaiv tau | |

| ● | photoelectric nrhiav kom tau ntawv tsis txaus ntawm daim ntawv pub zaub mov | txheem | ||

| 2 | Paper conveying thiab alignment pem hauv ntej-lay thiab sab-lay |

| ||

|

| ● | ntawv conveying system nrog lub tshuab nqus tsev | txheem | |

| ● | ob sab downward suction cua rub gauge | kom tsis txhob ntawv pem hauv ntej rub. | Txuj | |

| ● | Ob chav sab mechanical push gauge | tuab ntawv luam ntawv | Txuj | |

| ● | rub gauge / laub gauge hloov | ib tug yuam sij hloov | Txuj | |

| ● | daim ntawv nyob rau hauv qhov chaw photoelectric nrhiav pom | sab gauge nyob rau hauv qhov chaw nrhiav pom thiab pem hauv ntej gauge nyob rau hauv qhov chaw nrhiav pom | Txuj | |

| ● | Ib tus yuam sij hloov daim ntawv loj;ib qho tseem ceeb preset | sab gauge / pub txhuam lub log ceev ceev thiab txiav hauv qhov chaw | Txuj | |

| 3 | Lub tog raj kheej luam ntawv |

| ||

|

| ● | Ncej hom lub teeb yuag roller qauv | Me inertia, ruaj khov ua haujlwm | Txuj |

| ● | adsorption printing thiab tshuab stripping ntaus ntawv | Txuj | ||

| ● | anti rebound ntaus ntawv ntawm cov ntawv tuab | Txuj | ||

| 4 | Kev luam ntawv Framework |

| ||

|

| ● | Peb txoj kev hluav taws xob npo zoo hloov kho | Peb txoj kev hloov ntawm tej thaj chaw deb hluav taws xob screen | Txuj |

| ● | Non-stop ntsug thiab kab rov tav luam ntawv phaj calibration | Txuj | ||

| ● | tsis siv neeg them nyiaj rau luam ntawv ntev shrinkage thiab extension | Tsis siv neeg them nyiaj rau qhov hloov ntawm daim ntawv ntev los ntawm cov txheej txheem luam ntawv dhau los | Txuj | |

| ● | pneumatic locking ntaus ntawv | Txuj | ||

| ● | tus ncej txav ntawm nws tus kheej thiab disengages ntawm lub cuab yeej | Txuj | ||

| 5 | Pneumatic printing riam system |

| ||

|

| ● | Tsis siv neeg lub siab tsis tu ncua thiab tsis siv neeg hloov ntawm kev luam ntawv riam | Ua kom luam ntawv siab tas li thiab txhim kho kev luam ntawv zoo | Txuj |

| ● | Ceev thiab tsis siv neeg clamping ntawm luam ntawv riam thiab number case rov qab riam | Lub clamping quab yuam ntawm lub tshuab luam ntawv yog txawm, uas yog yooj yim los hloov lub tshuab luam ntawv riam (squeegee) | Txuj | |

| ● | ntse nqa nce thiab nqis | Raws li cov txheej txheem luam ntawv, teeb tsa txoj haujlwm ntawm rab riam / riam, txuas lub neej ntawm cov roj hmab scraper thiab cov mesh, thiab txo cov number case khib nyiab. | Txuj | |

| ● | ink drop ntaus ntawv | Txuj | ||

| 6 | Lwm tus |

| ||

|

| ● | pneumatic lifting system rau ntawv board | Txuj | |

| ● | tsis siv neeg lubrication system | Txuj | ||

| ● | kov screen tib neeg tshuab tswj | Txuj | ||

| ● | kev ruaj ntseg grating | Ua kom muaj kev nyab xeeb kom muaj kev nyab xeeb ntawm tus kheej ntawm cov neeg ua haujlwm | xaiv | |

| ● | tus neeg saib xyuas kev nyab xeeb | Ua kom muaj kev nyab xeeb thiab txo qhov cuam tshuam ntawm cov plua plav ntawm Kev Luam Ntawv | xaiv | |