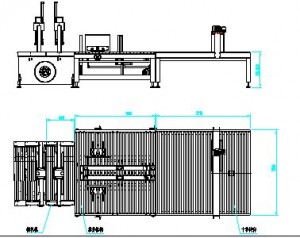

VISTEN Tsis Siv Neeg Flexo High Speed printing & slotting & kua nplaum nyob rau hauv kab

| Lub npe | Tus nqi |

| Khoom noj khoom haus (Lead Edge Feeder) | 1 |

| Lub tshuab luam ntawv (Steel anilox roller + roj hmab cov menyuam) | 6 |

| Slotting unit | 1 |

| Nws pib gluer | 1 |

Tsis Siv Neeg Flexo Printing & Slotter & Tuag Cutter Tshuab ntawm VISTEN

Functional configuration thiab technical parameters.

I. Khoos phis tawj tswj chaw ua haujlwm

1.Memory mus rau xoom: lub tshuab so version lossis me me ntawm cov phaj hloov hauv chav kawm ntawm lawv txoj haujlwm qhib lub tshuab, tom qab kaw lub tshuab tuaj yeem rov ua haujlwm qub.

2.Controlled anilox cov menyuam nqa: thaum ib pab pawg ntawm ib ntus tsis xav tau luam ntawv, tuaj yeem tswj cov pab pawg anilox yob tsis tas yuav poob, thiab yog li tsis tas yuav ntxuav tus number case roller.

3.Automatically trimming daim ntawv: dawb do teem lub sij hawm ntawm trimming daim ntawv ncua sij hawm kom lub lag luam hloov tau yooj yim, haum rau tus neeg ua hauj lwm cwj pwm

4.Position mus rau xoom: lub tshuab tuaj yeem ua rau lub phaj txoj hauj lwm mus rau xoom kom qhov chaw ntawm lub phaj tuaj yeem ua ib qho chaw, qhov kev ntsuam xyuas luam tawm ob daim duab tuaj yeem tshawb xyuas qhov chaw raug.

5.Main motor screen zaub ceev, pub, trimming, hla.

6.Lub vijtsam tso saib cov naj npawb ntawm kev txiav txim thiab teeb tsa tus naj npawb ntawm cov khoom siv tiag tiag, thiab lub tshuab tuaj yeem nres tau tom qab ua tiav kev luam ntawv, anilox tau nyob deb ntawm lub phaj.

7.Orders default: koj yuav tsum tau rau kev txiav txim nyob rau hauv lub computer xim screen tsuas yog yuav tsum tau nkag mus rau lub thawv ntev, dav, qhov siab thiab lub kaum sab xis txiav dav, trimming qhov dav ntawm tsib txhua cov ntaub ntawv txawj ntse cov ntaub ntawv kom tiav nyob ze lub tsev;(tuaj yeem khaws 999 xaj).

Cov ntaub ntawv muaj xws li:

(1) Qhov chaw luam ntawv ntawm txhua xim.

(2) Slotter txoj hauj lwm.

(3) Box siab txoj hauj lwm.

(4) Lub cartons pem hauv ntej dav, sab dav.

(5) Cardboard qhov siab, dav thiab lwm yam

Kev txawj ntse nyob ze ntawm lub tsev ncaj qha tom qab cov tswv yim ua tiav yam tsis muaj tus tswv tsev thawj qhov chaw ib qho kev taw qhia rau xoom thiab riam disk, baffle thiab thawj zaug rov qab mus rau lub hauv paus chiv keeb ntawm qhov rov ua haujlwm ntawm kev ua haujlwm qis.

8.Cov ntaub ntawv khaws cia: Thaum cov ntaub ntawv tau ua tiav cov khoom kom raug, cov ntaub ntawv tam sim no tau txais kev cawmdim rau kev siv tom ntej;tau hloov kho raws li cov lus qhia thaum siv dua, txuag lub sijhawm tswj hwm.

II.Feeding unit (ib unit)

Pub qhov tseeb: ± 1mm

1. Tshuab clutch

(1) Lub tshuab hluav taws xob tswj lub tshuab clutch txuas nrog lub tswb, cov lus ceeb toom txuas ntxiv mus, kom ntseeg tau tias muaj kev nyab xeeb ntawm cov neeg ua haujlwm.

(2) Txhua tus xov tooj hauv av thiab Taiwan, Cov cuab yeej siv thaum muaj xwm ceev nres hloov tuaj yeem tswj hwm sab hauv kom tsis txhob lub tshuab txav mus los, kom ntseeg tau tias kev ruaj ntseg ntawm cov neeg ua haujlwm sab hauv.

(3) Pneumatic interlock ntaus ntawv.

(4) Tag nrho tag nrho txoj kev xauv.

2.Absorbing plua plav system

(1) Nruab nrog lub tshuab ntxhua khaub ncaws plua plav tshem tawm, ntau tus lej los tshem tawm cov duab los qhia qhov tsis huv, thiab txhim kho kev luam ntawv zoo.

3. Pub cov menyuam

Sab nraud txoj kab uas hla ntawm lub Upper feeding roller yog Φ142.68mm. (1200)

(2) Seamless yeeb nkab, qhwv cov roj hmab hnav, thiab ua qhov kev sib npaug.

Cov menyuam hauv qab pub mis yog Φ157.45mm thiab embossed nyuaj chrome plating. (1200)

(4) Cov menyuam pub rau qhov sib txawv ntawm cov nplai cab iav hloov kho, qhov kev hloov pauv ntawm 0-12mm

.4.Second txheej ntawm sab sauv thiab qis pub rau menyuam

(1) Seamless yeeb nkab, qhwv hauv cov roj hmab hnav-tiv taus, thiab ua qhov sib npaug kho.

Cov menyuam qis sab nraud yog Φ157.45mm thiab embossed nyuaj chrome plating. (1200)

(3) Pub cov menyuam sib txawv kho los ntawm tus neeg, qhov kev hloov kho ntawm 0-12mm.

5.Qhov kev pub mis tsis siv neeg ua haujlwm tswj

(1), pub nyob ib ncig ntawm lub bezel, thawb cov duab los qhia tom qab thaiv lub thawv hluav taws xob hloov kho, thiab daim ntawv trimming muaj nuj nqi

(2), rov qab ncaws pob suction pab pub noj, raws li qib ntawm cardboard dabtsi yog khoov, ua qhov kev hloov ntawm huab cua ntim.(Yeem xaiv servo tswj lead edge feeder system)

(Peb lub tuam txhab ua tus thawj coj ntawm daim ntawv pub mis lub tshuab servo tswj, nrog kev ywj pheej ntawm cov cuab yeej cuab tam, thiab kev lag luam yog qhov pom tseeb heev, tsuas yog hloov cov qauv siv sij hawm uas tuaj yeem ua kom muaj kev siv ib txwm siv ntawm ntug feeder nrog synchronous taug qab, hloov cov khoom noj khoom noj seamless kis tau tus mob thiab lwm yam tshiab, tuaj yeem ua kom qhov tseeb ntawm cov khoom noj, kom tsis txhob rov qab tsis tuaj yeem daws tau los ntawm cov khoom siv cam kis tau tus mob, cov neeg kho tshuab hnav thiab tsim kua muag tom qab siv mus sij hawm ntev, kev hloov cov khoom noj tsis yooj yim, high-speed kis tau tus mob instability thiab lwm yam.)

III.Printer unit (ib xim ib txheej) (Optional scraper system)

Printing precision: ± 0.5 hli

1.Printing roller

1) ,Sab nraud txoj kab uas hla Φ393.97mm (muaj phaj txoj kab uas hla yog Φ393.97mm). (1200).

Sab nraud txoj kab uas hla Φ443.2mm (muaj phaj txoj kab uas hla yog Φ457.6mm). (1400).

2), nto sib tsoo, nyuaj chrome plating.

3), Dynamic thiab static tshuav nyiaj li cas kho, ua haujlwm du.

4), Ratchet tsau ntim version ntawm lub ncej.

5), Adopts dai mechanism kom yooj yim thiab ceev nruab, rau 10 hli dai version ntawm tsab xov xwm

6), loading thiab unloading printing phaj, ko taw hloov hluav taws xob tswj reversing.

2. Printing embossing cov menyuam

1)Sab nraud txoj kab uas hla ntawm Φ172.2mm.(1200)

2) 、 Hlau yeeb nkab nto sib tsoo, nyuaj chrome plating.

3),Kev sib npaug kho, kev ua haujlwm du

4) 、 Scale manually kho cov kev xav ntawm cov menyuam sib txawv ntawm 0-12mm

3, Hlau anilox cov menyuam (xaiv tau ceramic anilox cov menyuam)

1)Sab nraud txoj kab uas hla ntawm Φ206.65mm.(1200)

2) 、 Lub engraving textured steel nto nrog kev ua haujlwm tshwj xeeb.

3), dot, txawm nyob rau hauv number case, ruaj, thiab ruaj.

4), ncua sij hawm nyob rau hauv uas lub phaj thiab roj hmab cov menyuam lub neej, sculptured los ntawm ib tug tshwj xeeb txheej txheem.

4, roj hmab roller

1)Sab nraud txoj kab uas hla ntawm 外径为Φ211mm.(1200)

2), steel coated nrog corrosion-resistant roj hmab.

3), tshwj xeeb sib tsoo roj hmab cov menyuam, cov nyhuv number case.

5, theem kho mechanism

1)Planetary iav qauv.

2) Cov theem ntawm cov lus qhia cov duab digital kom ua haujlwm yooj yim dua, intuitive thiab raug.

3) 、 Lub sijhawm luam ntawv nrog PLC kov lub vijtsam tswj thiab hluav taws xob digital 360 hloov kho (kev ua haujlwm nres tuaj yeem hloov kho).Phase modulation raug txog li 0.15 hli.

4) Print roller inverter yog siv los kho cov theem, dynamic thiab zoo li qub nyob rau hauv txhua txoj hauj lwm kev hloov kho, zoo-tuning raug mus txog 0.10 hli, xws li qhov chaw dislocation yeej ib txwm rov qab mus rau xoom tom qab chav tsev tau raug tshem tawm, raug mus txog 0.5 mm.

6. Ink ncig

1), pneumatic number case twj tso kua mis, ink stability, yooj yim khiav lag luam thiab txij nkawm.

2), lub xeev tus cwj mem ntxuav cov cuab yeej, uas tuaj yeem txuag tus number case zoo.

3), lim dej lim, lim cov impurities.

7, lub sij hawm luam ntawv fixtures

1), electromagnetic nres nres mechanism.

8, axial adjustment mechanism

1), hluav taws xob axial hloov kho mechanism.

2), digital display hom qhia txoj hauj lwm, ua kom lub lag luam yooj yim dua, intuitive thiab raug.

IV.Slotter unit (ib teev)

Qhov siab precision: ± 1.5mm

1, kab xo

Ncej txoj kab uas hlaΦ154mm, tom qab ob sib tsoo, nyuaj chrome plated, du txav.(1200)

2) 、 Kab nias cov menyuam sib txawv ntawm qhov ntsuas phau ntawv hloov kho, qhov kev hloov kho ntau yam 0-12mm.

3) 、 Cov kab siab nyob ib puag ncig siv cov khoom siv zoo polyurethane

2.Slot riam zawv zawg hloov kho mechanism

1)Ncej txoj kab uas hla Φ174mm tom qab ob sib tsoo, nyuaj chrome plated, du txav.(1200)

2) 、 Slotted riam dav ntawm 7mm.

3) 、 Alloy cuab yeej steel kub-kho, sib tsoo toothed slotted riam, hardness thiab toughness yog superb.(Taiwan)

4) 、 Alloy steel tom qab kev kho cua sov, sib tsoo txiav riam, ntse riam, thiab siab precision.

5) 、 Cov kab hluav taws xob lub log, cov lus qhia rau cov menyuam, qhov riam hlais txoj haujlwm, kev siv hluav taws xob khawm synchronization tswj.

6) 、 Cov kab hluav taws xob lub log, cov lus qhia rau cov menyuam, qhov riam hlais txoj haujlwm, kev siv hluav taws xob khawm synchronization tswj.

Slotted theem kho mechanism

1), lub planetary iav qauv.

2), ua ntej slotting theem, tom qab riam nrog kov npo thiab hluav taws xob khawm dual tswj thiab hluav taws xob digital 360 degrees (nres tuaj yeem hloov kho dynamically).

3), slotted riam kab rov tav txav txais kev hloov hluav taws xob (stop dynamic tuaj yeem hloov kho).

VI.Glue System:

1.Kev saib xyuas yooj yim, txo cov nqi tu.

2.Peristaltic twj tso kua mis lub voj voog, txo cov khoom pov tseg.

Chaw Thauj Khoom:

Muaj peev xwm tiv nrog ntau yam tuab ntawm cov duab los qhia nrog qhov sib txawv kho cov cuab yeej, tau txais los ntawm cov xovxwm tawm ntawm cov duab los qhia ntsug.

Folding Unit:

1.Installation tshiab folding system, nyob rau hauv kab ntawm lub meej folding, trimming qhov sib txawv yuav nce thiab nqis.

2.Siv suction hom siv lub ntsiab, qhov paug tawm ntawm cov theem kawg hauv lub thawv folding, cov duab los qhia cov npoo kom tsis txhob cuam tshuam.

3.Sab laug thiab sab xis ob txoj hlua khi nrog lub cev muaj zog sib cais, raws li qhov ntev thiab dav qhov ntev ntawm tus kheej tswj ceev.

Kev suav thiab Eject unit

1. Cov duab los qhia me me tuaj yeem ua tiav kev ua haujlwm siab nrawm.

2.Externally bonded type, portable hole, vent-type can also be stability, smoothly stick the paper box.

Chav ua haujlwm:

1.Configure xim LCD kov npo, koj tuaj yeem tso saib ntau yam ntaub ntawv ceeb toom thiab cov ntaub ntawv ua haujlwm.

2. Ua tiav cov chaw taws teeb tswj.

VII.Cov iav kis tau tus mob

Lub ntsiab tsav iav

1), los ntawm 20CrMnTi alloy steel, carburizing thiab sib tsoo zog.

2).

2. Lub nplhaib sib txuas

1) Lub nplhaib sib txuas pub dawb, tuaj yeem txuas nrog lub ncej thiab lub iav, kev siv lub zog loj yuav tsis sib txawv, kev teeb tsa thiab kev saib xyuas yooj yim dua, tso cai rau lub tshuab tsav tsheb mus sij hawm ntev los xyuas kom meej cov ntawv sau npe.

VIII.Main technical parameters

| Specification | 2500 * 1200 hli | |

| Max ceev (pcs / min) | 160 | |

| Max pub mis loj (mm) | 2500 * 1200 hli | |

| Kev pub mis tsawg (mm) | 650 * 330 hli | |

| Hla kev pub mis loj (mm) | 2500 * 1400 hli | |

| Thickness ntawm daim ntawv (mm) | 2-10 | |

| Max luam ntawv loj (mm) | 2450 * 1150 hli | |

| Print phaj qhov tob (mm) | 7.2 | |

| Min slotter ncua sij hawm (mm) | (mm) Kev txiav zoo | 120 * 120 * 120 hli |

| (mm) Rov qab txiav | 200 * 80 * 200 * 80 hli | |